![]()

In 2005 I learned techniques for

throwing large pieces. Having tried several of these I found a way of working which

enabled me to create the pieces illustrated here.

I began by throwing large forms and then closing the pieces - the first forms I arrived

at were torpedo shapes, which could be achieved by continuing to throw then closing the

top; a technique I found more difficult than making an inverted top on the wheel then

attaching this to the body by scoring and slipping the edges, which is how these

pieces were constructed.

I discovered that closed forms trap air, which meant that pressure could be applied to

the outside to alter the form while the air pressure inside kept the pieces from

collapsing. I decided that these closed forms would make an interesting starting point

from which to build a collection and did some rough sketches on paper to explore

possible forms.

These acted as a guide only as working on the actual piece involved constant reappraisal

to achieve a form that I felt was interesting and well-proportioned while working within

the limitations of the material (I did not know at that point if a shape such as that

of Terebellum would survive a firing without distorting or slumping as it had a broad

circumference supporting a large conical shape - see below)

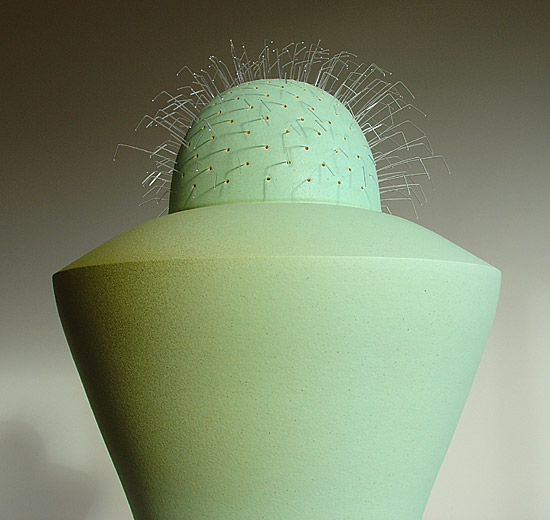

Terebellum 75 x 40 cms

Throwing a base and allowing it to stiffen before adding coils to construct the walls gave

me a firm base on which to build without the piece collapsing. I would roll out coils of

JB3, a white stoneware clay, and join them before attaching them to the rim and

continuing to throw. The 'tops' I would make separately and attach later. Deneb, for

example, consists of three pieces, a base, a platter which forms the shoulder of the

piece first thrown then inverted and attached and finally a bowl sunk into the

hollow at the top. (Air pressure tried to force the bowl out again so it had to be

held in place until the slip had stiffened forming a stronger bond).

Deneb 33 x 35 cms - constructed from three thrown pieces

![]()

Mekbuda, the tallest piece in the group photograph, was approx 1 metre 10 before firing

and in order to throw the top part I wedged a brick on the wheel's pedal to keep it

turning and stood on a stool to reach the top. Tall pieces such as this tend to wobble

when spinning; I discovered that a 12 inch metal ruler applied pressure evenly over a

greater surface area and prevented chattering (where the turning tool jumps over the

rotating surface), enabling me to achieve more precise, smooth symmetrical curves

than I could with more conventional turning tools.

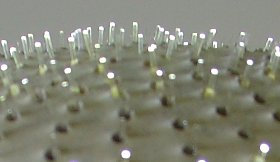

I had made some earlier vessels parts of the surface of which I decorated with small

indentations forming patterns of dots, from this idea developed holes then the idea of

spines like cacti, which I have grown for many years from seed and whose architectural

forms are also a great source of inspiration.

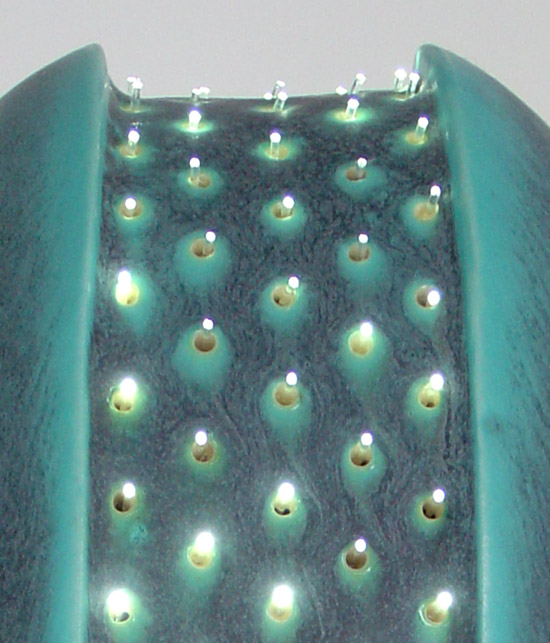

Using a spray booth meant I could get an even coating of glaze using

relatively small amounts - approximately 1 litre for the larger pieces. To ensure that

the glaze did not fuse over the hole

made for the fibre optic cable, I cleaned the glaze out of each hole with an

inter-dental brush prior to firing. This caused thinning of the glaze around the edge

of each hole giving a marked tonal effect, which is clearly visible in Tarazed where

the glaze ’breaks’ (appears lighter) around the holes and on the carved vertical edges.

Tarazed 79 x 14 cms - the glaze ’breaks’ to a paler turquoise around the holes

![]()

On a trip to India In 1999 I found the illuminated dashboard displays in the taxis of

Buddha and other deities moulded in perspex and illuminated with accompanying fibre

optic cables very appealing and made a mental note that I would like to work with light

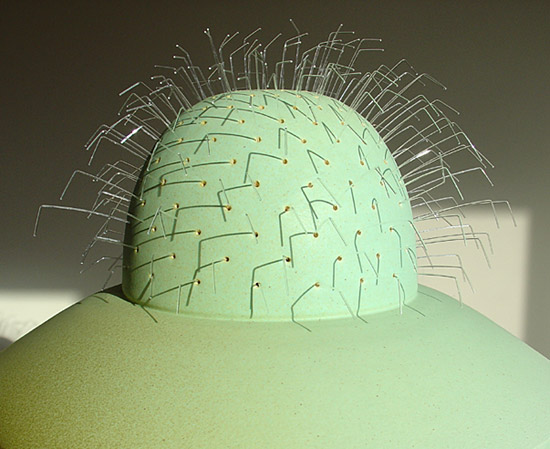

in some way. I decided to incorporate

fibre optic cables into ceramics. Each fibre is cut to the approximate length

required and threaded through the hole and out through the base of the piece. The

top end of each cable is bent to prevent it falling through then glued into place

before finally being cut almost flush with the surface.

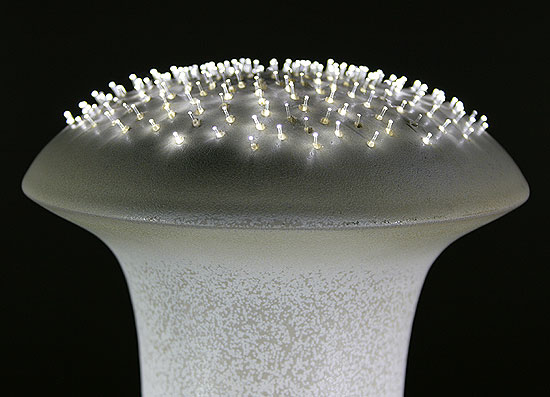

Sol 45 x 32 cms - installation of fibre optic cables

Sol 45 x 32 cms - installation of fibre optic cables

![]()

Finding many of the available glazes unsympathetic to the pieces I was making I embarked

on an intensive research programme with the support of Ian Currie’s excellent book:

’Stoneware Glazes - a Systematic Approach’, to develop a range of matt and satin matt

glazes more suited to the larger vessels and sculpture I was creating. I found variegated

glazes more appealing than uniform ones, particularly as they often exhibit variation

across a surface, which can be seen in the magnesium glazes on Syrma and Procyon, both

of which use titanium dioxide, which I used extensively to achieve a mottled effect.

Syrma 64 x 17 cms - magnesium glaze

Sources of Inspiration

I find I have a stronger aesthetic response to form which is apparently uncomplicated, but often reveals greater complexity on closer examination enhancing it and imparting a subtle shift from one state to another: shiny to matt; dark to light; opaque to translucent. I find the fractal quality of natural phenomena and iterative structures very appealing whether in the music of Brian Eno or Steve Reich, or in the undulating spine formations across the surface of a cactus or in the refraction of light across hundreds of windows in a high rise. Thus in the installation entitled ’vol_Luminous’, although each piece may stand alone, it is in the juxtapositioning of similar forms illuminated and unified with white light that creates impact and attempts to engage the observer in a dialogue with the work.I enjoy evolving an idea: exploring the permutations of form and expression of materials in the creation of a body of work which is self-referencing and has an integrity without necessarily having explicit reference to something in the real world. Observers have likened the pieces to marine forms, jellyfish, futuristic cityscapes and exotic forests. I find that the pieces exhibit both an industrial and an organic aesthetic. I find it challenging to attempt to create work that is ’quiet’ yet has a strong presence; a quality I find in the sculptures of Anish Kapoor for example. These notions, together with inspiration from contemporary architecture and industrial design, lead me to create the installation entitled ’vol_Luminous’.

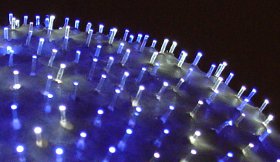

Light Emitting Diodes

Embedded In the wall of each sculpture towards the base is a tiny socket connected to the LED inside, which illuminates the bundle of fibre optic cables. The LEDs require very low voltage: for a single piece a mobile phone charger is plugged into the sculpture; for installations of three or more pieces a single power point is all that is required as a series is run from a single dedicated Philips LED driver. This permits a flexible, modular system in which the pieces can easily be interchanged and relocated. A piece can be plugged in and out of the series; i.e. they are not all ’hard-wired’ together. The LEDS, which illuminate the fibre optic cables, are new generation, high intensity LEDs with a manufacturer’s estimated life of ten years. The LEDs can easily be replaced.The light emitted by these objects lends to their placement in rooms and hallways where subtle, ambient, nighttime light is required. Since the pieces sparkle at night I named each piece after a star and now, rather surprisingly, images of the pieces often appear in a Google image search before those of their eponymous giants.